Staff note: This post may contain affiliate links, which means Pentax Forums may earn a small commission if a visitor clicks through and makes a purchase. If you would like to support the forum directly, you may also make a donation here.

Hi, this is going to be my first useful post on the forums, I hope it will also be helpful to someone out there.

After accumulating a number of Takumar lenses in the last 2 years, lack of funds for maintenance and repair made me pick it up myself, and slowly get better at it. In my experience, the Takumar myth of greatest, smoothest focusing rings hasn't quite stood up. Yes, they are miles ahead of Soviet lenses, but lubrication does dry out after some 40 years. Of course, sample variation plays a huge role here, and I do realize that I have always bought the cheapest ones I could find, but nevertheless, even some of my minty ones had old age issues. I am sure that my lenses are not the only ones that had problems with stiff focusing rings and aperture blades, fungus and falling distance scales. In fact, even ugly ducks can provide surprises sometimes (hey, check out Susan Boyle!).

Enough with me rambling on and let's get to today's lens. I have selected the 55mm f/1.8 to exemplify some general concepts in Takumar disassembly. It didn't really need to be dismantled, but the focusing ring was just a

little stiff for my liking, and I wanted to document a disassembly since I had received my flash back (my natural light is horrible).

I will guide you through some important aspects that are generally avoided in online tutorials, such as how to properly assemble the focusing helicoid from scratch. My guide will be based on

this one, which is a fantastic guide in itself, and even I learned a lot from it, but nevertheless it has some important shortcomings, one of which is the not-so-reader-friendly language (mine isn't great either, but at least I'm trying!).

The lens parts are stacked together, so in order to gain access to the mount, you have to disassemble it all the way from the front. Later K-mount lenses introduced a second access from the back.

So here is the lens. I pay great attention to detail, so I do care where the writing on the name ring will end up. I like "Super-Multi-Coated Takumar 55mm" to be at the top, because I find it more important when I look at it, rather than the serial number, or Asahi Opt Co. So I note with a marker where the top should go, and only then I proceed to unscrew the name ring. Under it lie 3 screws, and thus the ring can fit in 3 circular permutations. When reassembling, I take care that the part which should be at top really is there.

The images are pretty self-explanatory, so I won't describe the steps in too great detail.

0. Take notice of the distance pictured here. I will call it "focusing ring offset", and I will explain later why this is important.

1. Unscrew the name ring using a friction tool. DO NOT drill holes in it, better sell it to someone with more patience than you. Even if the filter ring is bent, it can be bent back into shape.

2. Remove the 3 flat screws, I have already exhausted the subject above. Although this is a S-M-C lens, it appears that they didn't use JIS until the rubber focusing ring SMC. Other lenses already used the JIS cross-type screw by this time.

3. With the lens focused at infinity, remove the focusing ring.

4. Now focus the lens all the way past infinity, and take notice of the distances marked in the picture. You will have to redo infinity focus, and the 3 holes in the brass piece have to be at a distance from the other 3 from the ears, otherwise you won't be able to tighten the screws if they are right under the ears!

5. Remove the distance scale ring. I use for this operation the thinnest blade knife I have. The ring is held by 3 very small set screws. Do not remove the screws completely, just loosen them!

This is how your lens should look at this point.

6. Remove the aperture ring. Be careful about the ball bearing. I also remove that so I don't lose it.

7. Remove the 3 screws that are holding the helicoid block and the mount piece together. Strangely, these are JIS type, at least in my copy, so you will need special screwdrivers for them, sorry.

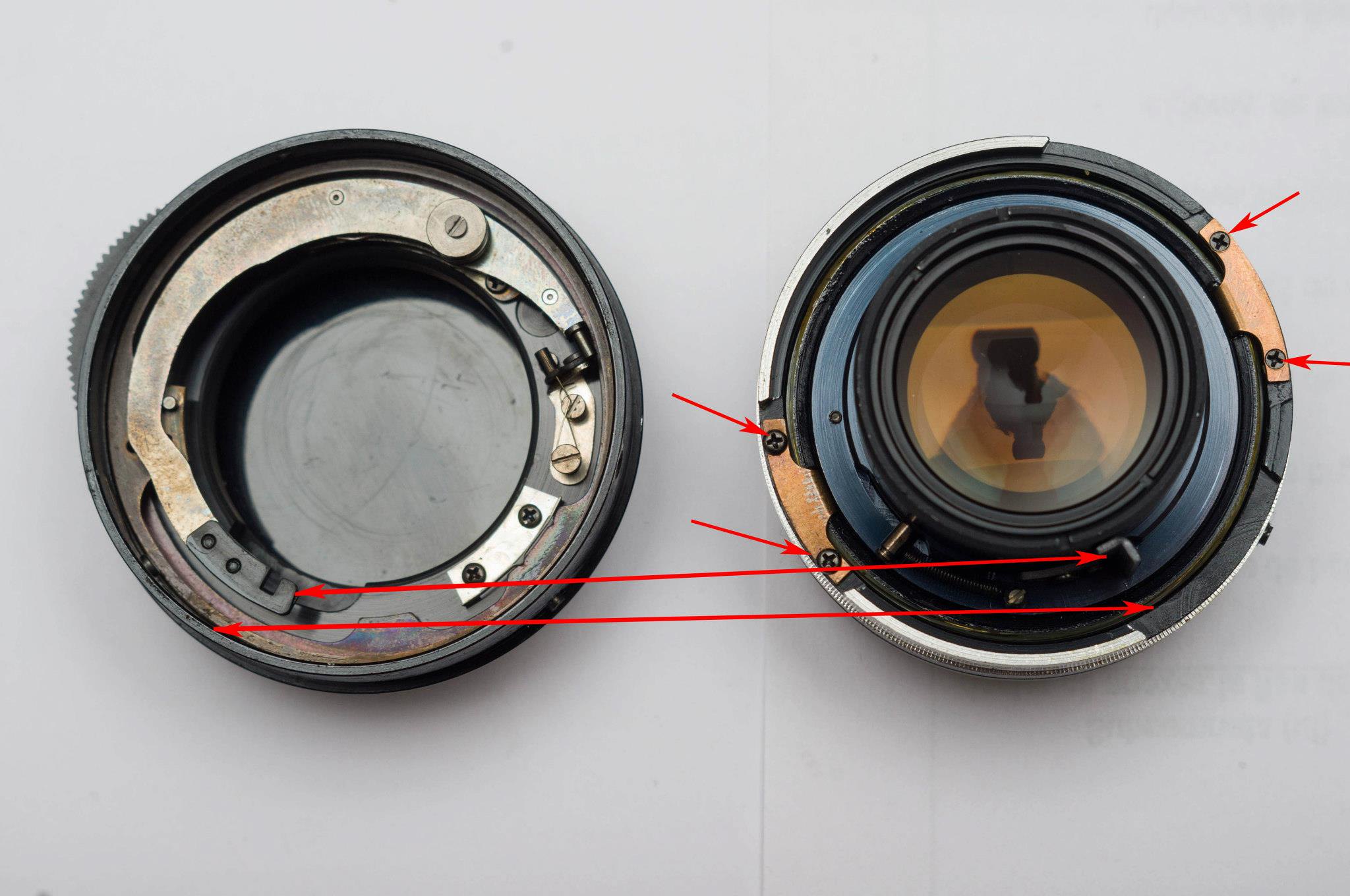

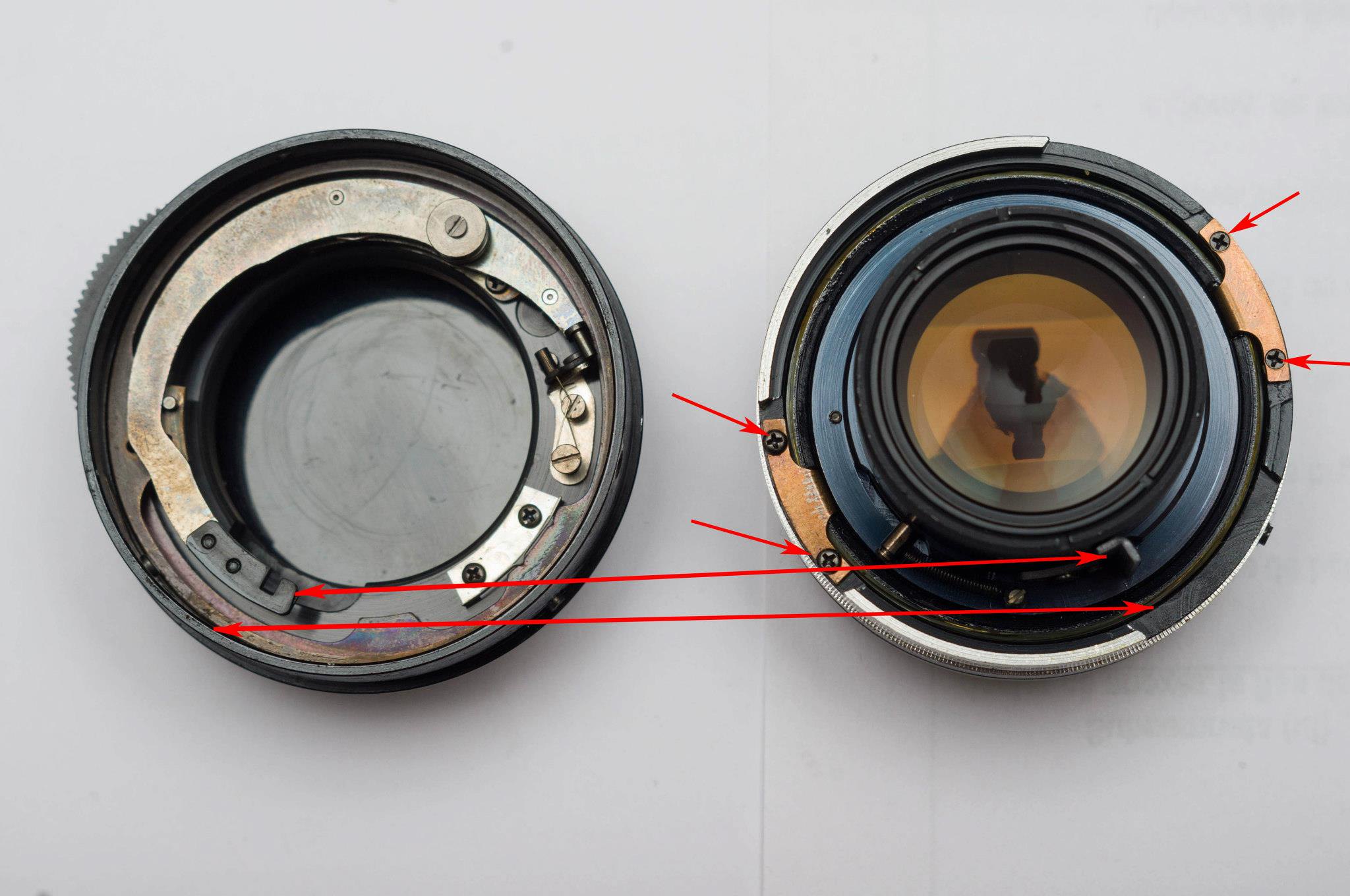

8. When taking the two pieces apart, take notice how they should fit together. There are just 2 contact points, figured in the picture: the F-shaped aperture lever with the corresponding lever on the optical block, and a groove near those. The groove is absent on some lenses, like the 50/1.4. Generally speaking, the groove should be on the same side as the aperture lever. You will need this information when reassembling.

My copy was very weird in some aspects: it must be a very early S-M-C example, because it has no open-aperture contacts. The spring-loaded aperture lever was also the first I saw in a Takumar, and the L-shaped pieces normally mount differently too. But all principles remain the same.

9. Our purpose is to dismantle the focusing helicoids completely, for cleaning reasons. On the 55/1.8, you can achieve this in two ways: either focus it all the way towards minimum focus distance, and the helicoid will be ejected, or unscrew the L pieces. I will explain the role of those in a moment.

The helicoid is comprised of 3 moving parts: one belongs to the optical block (1), one is the brass piece (2) and one is the black aluminium piece (3). The black and the brass piece are threaded together opposite to normal direction. The L pieces reduce the number of moving parts from 3 to 1, by connecting (1) with (3), so that only (2) is able to move. When (2) screws into (1), it also unscrews from (3), and vice versa, because they are threaded differently.

Now you have a basic principle in your mind of how the focusing mechanism works. Disassemble everything you see and clean with isopropyl alcohol/naphta/Zippo lighter fluid/whatever floats your boat. That stuff is old and gummed up by now.

10. Not only cleaning (1) and the interior of (2) is important, but also the exterior of (2) and (3). In fact, this is the critical part for smooth focus. I use a different, lighter grease for this, because I want it to be really smooth. In fact, I combine my usual grease with a PTFE-based lubricant spray to make it lighter. Worked great so far, but that's my dirty little secret.

11. Now it's time for reassembly. It is just the reverse process of disassembly.

Kidding! I just hate it when I hear that. Mainly because it totally isn't. You have to rethink the lens from its core to reassemble it. So here's how to do it.

The brass piece, (2), has multiple entrances on the inside threads (which go into (1)). I haven't counted them, but it is a finite number smaller than 5. If you approach the problem systematically, it won't be a problem. So pick one randomly, and thread (2) and (3) into (1) completely. Then unscrew (3) from (2) just enough so that the L pieces are in the right place. You will understand when you have the lens in front of you. Generally, if (3) needs more than an 180 degree rotation from fully screwed to its correct position, then you should pick a different entrance.

Basically it doesn't matter which entrance you hit, but here's why it actually does:

Remember what I told you about step 0 and 4? Read them again. Some of the entrances will result in holes right under those 3 ears, which is not what you want. Also, the entrance you pick will also give different focusing ring offsets, because of different degrees of rotation necessary for the (3) ring (discussed above). Too small an offset, and it will jam your focusing ring. Too large, and it will just look wrong.

So basically this is the step where I can't give you the fish, however I can teach you how to fish. I wish you best of luck and a lot of patience.

12. Once you have done the above for one possible entrance, mount the L pieces again, (IMPORTANT!) focus it towards minimum focus distance, and place the whole assembly into the mount piece, with the rules described at step 8. Tighten the 3 JIS screws. Go to a window, mount the lens on a camera (with live view or any focusing aid would be preferred) and focus on the farthest object you can see. The moon makes a good candidate for this.

Take notice where the 3 holes in the brass piece will end up. If they are under the ears, you're in the wrong entrance. If not, move on.

Mount the ball bearing, aperture ring, distance scale (without tightening the screws!) and the focusing ring. Tighten the screws holding it. If it gets jammed, then the offset is too small, and you're in the wrong entrance again. You have to disassemble everything again. If it is alright, then your lens is almost done. You just have to mount back the filter ring.

If you're anything like me, you won't believe me that these things really matter, and you could have reasons to do so. So I will show your some lower quality pictures taken of my 35/3.5 and 50/1.4, illustrating different entrances. In the second picture, the holes are under the ears, and you can't see them, let alone tighten them. Actually, you will notice that the 50/1.4 has 4 holes. One was drilled by a repairman that got fed up with the original 3 holes always ending up under the ears. He simply didn't have enough patience to find the right entrance, it was a pain for me too actually.

I really hope this is of use, because it took me a lot of time to write it, and I'm really sleepy now. I will correct it if there is anything I have missed.

Similar Threads

Similar Threads

Post #1 by kcobain1992

Post #1 by kcobain1992