I know this is supposed to be a sarcastic thread, but I feel the need to weigh in on drills, and drilling.

You see, I drill holes for a living.

In aviation manufacturing drilling is what it is all about. Selecting the correct drill motor, and the correct drill are critical for perfect hole quality. A good hole ensures that the airplane will carry people and goods safely for the 20 to 30 year designed lifespan of the aircraft.

I drill holes using a variety of drill motors (all air powered), and a variety of drill bits designed for the various stack ups of materials.

Since airplanes are made of exotic materials, i.e. aluminum, titanium, stainless steel and CRES (a type of steel alloy), fiberglass and carbon fiber, each drilling operation requires a specific drill bit, and a drill motor designed to perform the operation.

There are cobalt drills, high carbon drills, double margin drills, single margin drills, unicorn bits, dreamer bits, core drills, reamers, gunbarrel drills, the list goes on. There are drill bits only 1/4" long, and drill bits that are nearly 2 feet in length.

There are many different types of drill motors too. High speed and low speed. Ordinary drill motors most of you would recognize as a drill, and drill motors that have elaborate gear driven mechanisms that allow drilling offset from the axis of the drill, even around corners. There are devices that connect to the drill motor to reach into areas that otherwise cannot be accessed, called a zephyr, that do a great job of pinching fingers. Most of the hand held drills have quick change chucks that only take bits with a special end that matches the chuck, but we do have some straight shank drill bits that require an ordinary drill chuck and key (3/8" and 1/2").

There are self feeding drills that mount into tooling that holds them over the area to be drilled. The are called "quacks" for the name of the company that made the first ones, Quackenbush, but there are also Seti Tech versions. Kind of like a drill press, only portable. They connect to the shop air and a pump that feeds lubricant through holes in the drill bits which not only lubricates the drilling operation, but cools the cutting end of the drill bit. Drilling with quacks makes holes up to around 2", through stack ups of materials several inches thick.

The latest thing is robotic drilling. Parts are clamped up in a jig fixture, and then the robots drill most of the holes. What the robots can't do, humans finish.

For the last 3 years I have been drilling almost entirely by hand, working the upper trailing edge of the 777 wing, but recently I was moved into the 777 spar shop, working a section of the rear spar. I drill a few holes by hand, and then index a bunch of parts with locating jigs, set up the quack plates and run quacks and seti techs for a few hours. Messy work, with lubricant and metal chips everywhere, coveralls are a must. But a fun way to spend the day, I like to think of it as controlled destruction. After the drill up is done, I clean up the mess, debur and fillet relieve the holes and call it a day. The next day I install the parts I drilled the day before.

The third day I repeat the process on the other wing spar (if I drilled and installed the right spar first then the left spar is next, then after that, I go back to another right spar.

Some drill images from the innerwebs:

An Ingersoll Rand 6,000 rpm hand drill with quick change chuck and single margin drill bits. A drill motor like this runs about $1,000 US.

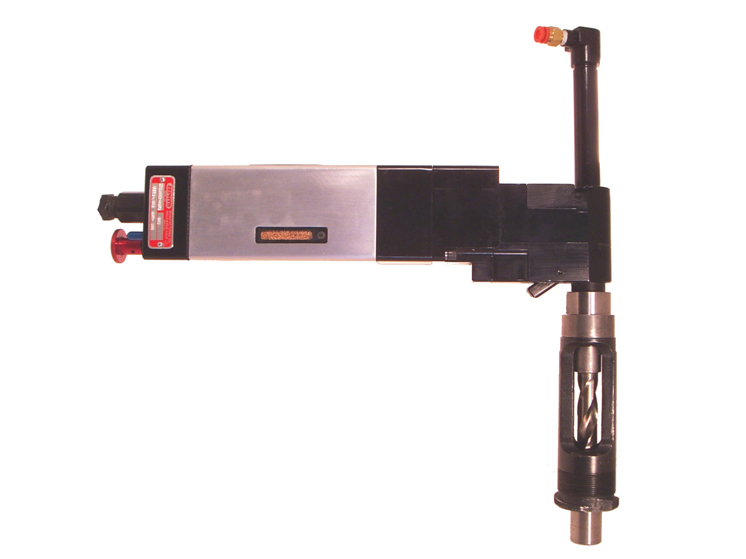

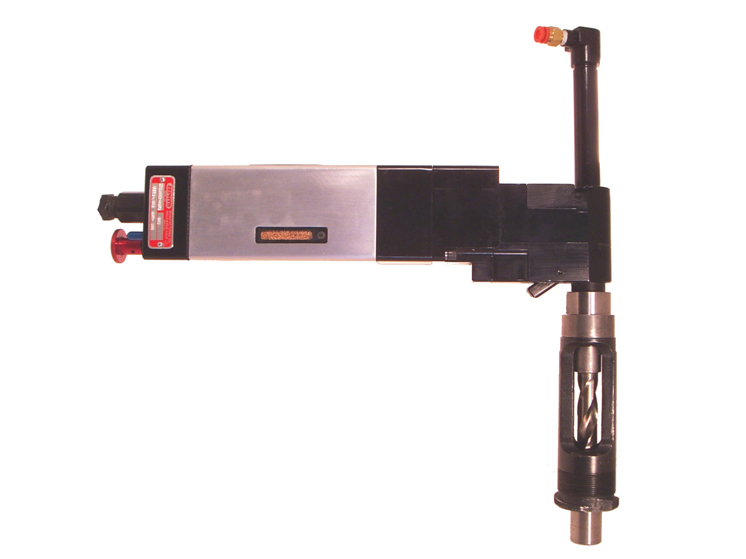

One type of quack drill with integral lubrication reservoir. Cost: several thousand dollars.

A quack drill. (not actually a Quackenbush, but similar)

A quack lube pump.

Similar Threads

Similar Threads

. Newer phones will have more features (portrait bits, etc.), but I'm not sure it's compatible with the latest headphone-jackless models. An android version is coming afaik. The only danger is pocket drilling - be sure to remove the bit when you stow it or you may be in for some pain.

. Newer phones will have more features (portrait bits, etc.), but I'm not sure it's compatible with the latest headphone-jackless models. An android version is coming afaik. The only danger is pocket drilling - be sure to remove the bit when you stow it or you may be in for some pain.

Post #7 by twilhelm

Post #7 by twilhelm