After sitting idle for a few months, I fired up my K-30 to find it was taking black photos only. After some basic troubleshooting, it was obvious that the aperture was closing down all the way, no matter what the camera said it should be. So some internet searches led me here because it seems the only technical article is from a Russian site. One of the members here was good enough to translate it for us, so at least I had a basic understanding of what to look for.

Since I have a long background in electronics troubleshooting and working on small delicate items, I decided to dig into my K-30. It was useless and not worth anything as it was, so what's to loose? Here I'll explain how I did it, and maybe help others that find themselves in a similar situation.

So let’s get started. For the sake of clarity, the right and left sides of the camera are when viewed from the front. Also, work with a body cap to protect all the innards, and keep small parts from flying in there.

1) Remove the bottom plate: Remove all the screws holding the bottom plate. Make careful note of which screw came from which hole. Some screws are fine thread for metal and some are coarse thread for screwing into plastic. There are 3mm, 4mm, 6mm, 7mm and 10mm screws. While you’re at it don’t forget the silver screw down inside the battery compartment. There is a total of 13 screws.

2) Remove the top cover: WARNING: (I hate stupid warning messages, but this IS important, so DON’T take it lightly. The flash capacitor is directly under the PCB that you will be desoldering wires from on the right side, and areas near the PCB do have some “juice” that can give you a NASTY JOLT – one you won’t forget! Be very careful).

Slide the rubber eyepiece up to remove it. There are 2 screws under it that need to be removed. Remove the 2 screws just inside the loops for the neck strap. There is another screw on the right side just under the button for the pop-up flash. Now pop up the flash and remove the 3 screws inside the front. There is a total of 8 screws. The top cover is not difficult to remove at this point. A thumbnail pressed into the top cover seam is all that is needed to get it started. Be gentle. If you pull too hard and it suddenly pops off, the wires inside will most likely get ripped off their solder pads. There is a total of 6 wired to be unsoldered.

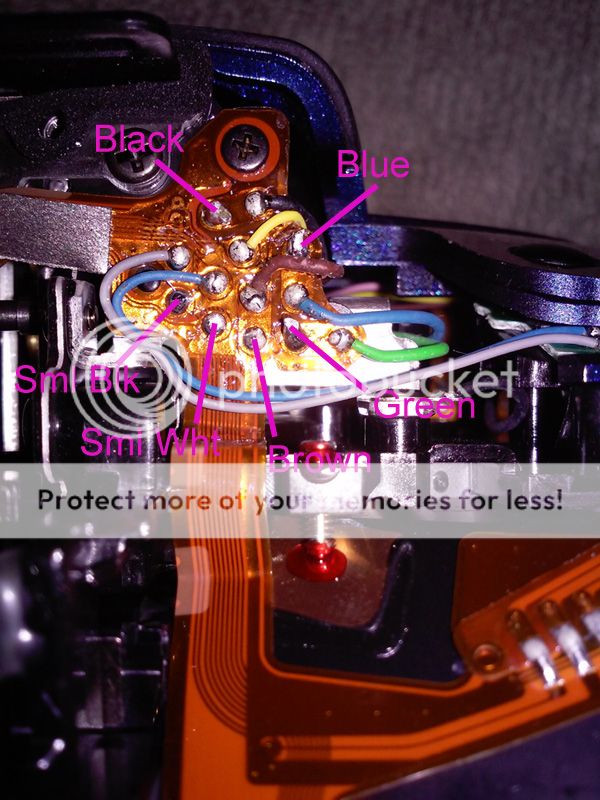

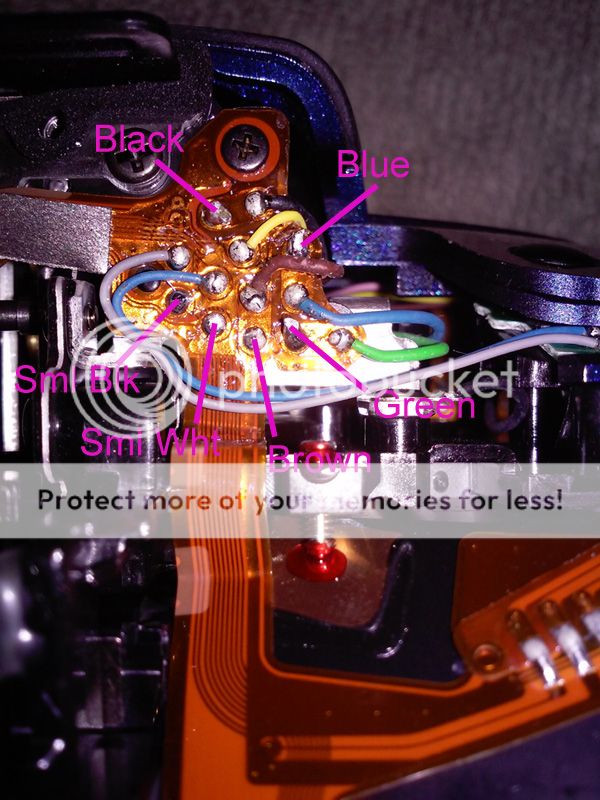

3) Unsolder the wires from the PCB on the right side. Position the camera as shown below to minimize the stress in the wire leads. Make note of their locations and unsolder them. (Remember that warning above????)

4) Remove the ribbon connector on the left side.

5) In case you lose track of where the wires go, this should help.

6) Remove the front cover: Remove the rubber grip on the right side of the camera. There are 2 screws underneath. Peel back the left rubber grip slightly and remove the first screw that appears. Lay the rubber back down – there is no need to remove it. Remove the other screw on the left side near the DC power jack. There is one more screw on the bottom between the projections for the lens and hand grip. There is a total of 5 screws. The front cover should pop off – there are no wires connected to it.

7) With the 3 covers removed, we can get to the solenoid. It’s just to the left of the large silver cross in the center of the photo. Unsolder the 2 wires. You will need a long small jewelers size Phillips screwdriver to remove the screw that holds it in place. Now just pick it out by the steel frame, not by the copper coils!

8) Here’s the culprit. The solenoid is shown in it’s activated position, locked in place, even though there is no power applied. When the solenoid is activated, the horse shoe shaped plunger (the bottom piece of steel) is pulled up into the 2 coils, as shown. This activates the arm that controls the aperture opening. The vertical slit in the top of the frame has a powerful neodymium magnet inserted into it. The problem is that the plunger is pulled in so far that the legs of the horse shoe hit the highly magnetized frame at the top of the solenoid. The magnetic pull is so great that the horse shoe plunger is locked in place very solidly. I didn’t think to measure the amount of force to pull the plunger back out, but it has to be at least a couple of pounds. That magnet is surprisingly powerful.

9) Since I didn’t want to make any permanent changes that couldn’t be reversed, I elected to fill in the gap at the bottom of the horse shoe, and then add another .25mm so it would bump the plastic solenoid coil form before the top end of the legs could get magnetically locked to the upper steel frame. So I filled the bottom of the of the horse shoe with solder and then carved it into shape with an x-acto knife (with a new blade) so the legs are now only 3.37mm long, as opposed to the original 3.87mm long.

10) At this point, I put it all back together by just reversing the whole procedure. The camera is taking fine pictures again, and for 0$$. Total time was about 3.5 hours. If you want to try this yourself, here are a few pointers:

Be patient and think things out.

Be gentle - it's a delicate item with even more delicate parts inside.

Have a large, clean and organized work area.

Spread out a clean bath towel over your work area - small parts do not bounce off of a towel.

Last edited by Clover-Leaf; 12-17-2016 at 08:45 PM.

Similar Threads

Similar Threads

. My old K-50 developed the problem after being stored for some time, I can still get it back to life, but it happens every time when I start it, gone try your approach, but will try to shorten the legs, maybe round them on the tips a bit to decrease surface area, the k-50 is backup at them moment barely rarely use it after I bought the K-1 .

. My old K-50 developed the problem after being stored for some time, I can still get it back to life, but it happens every time when I start it, gone try your approach, but will try to shorten the legs, maybe round them on the tips a bit to decrease surface area, the k-50 is backup at them moment barely rarely use it after I bought the K-1 .

Post #1 by Clover-Leaf

Post #1 by Clover-Leaf